In the rapidly evolving landscape of manufacturing and engineering, finding ways to cut costs without sacrificing quality is an ongoing challenge. For decision-makers in engineering and manufacturing departments, the pressure to produce production-grade parts efficiently and economically (the first time) is a constant dilemma.

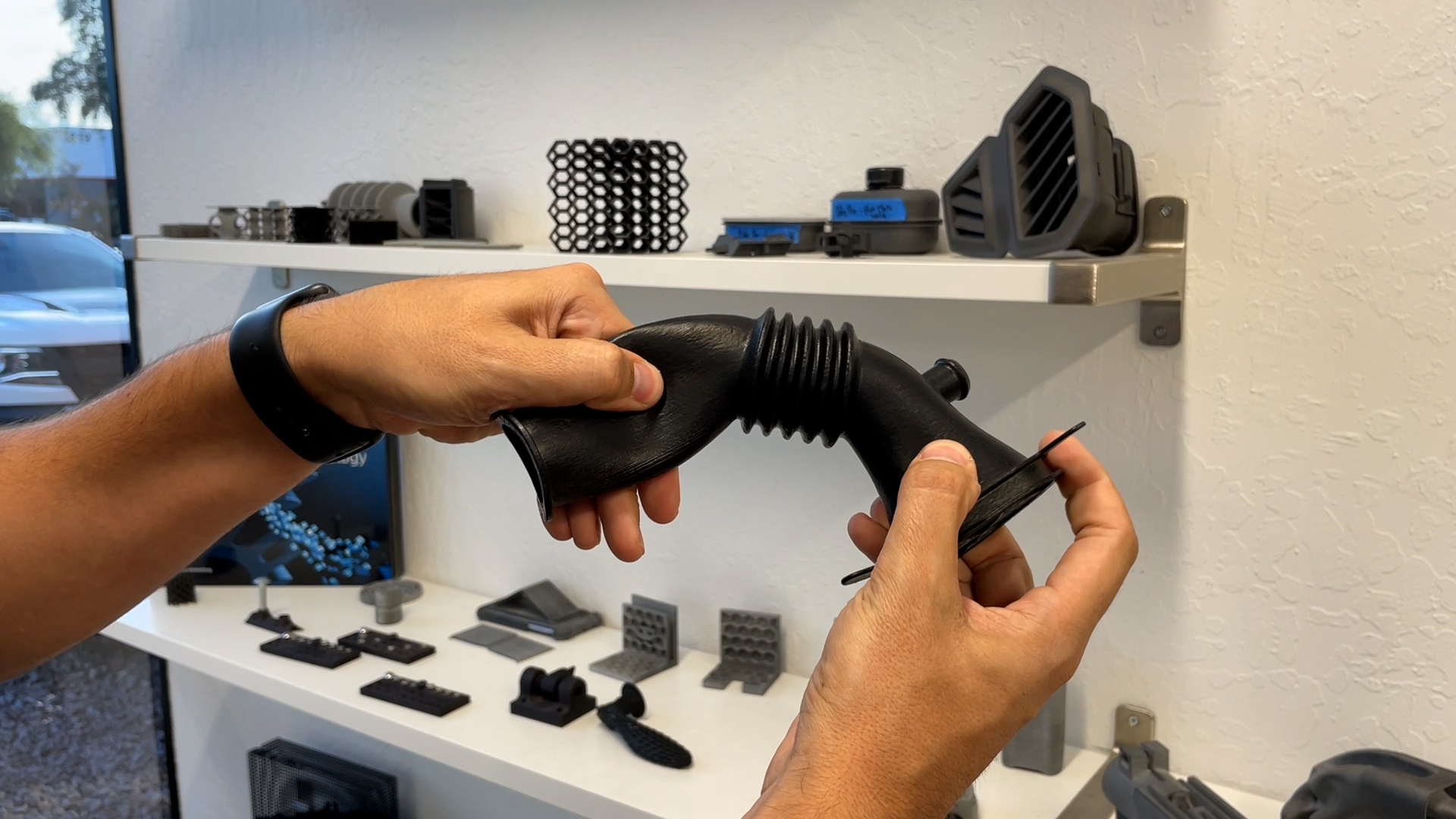

Traditional manufacturing processes have served us well for decades, but as technology advances, so do the opportunities to streamline and economize. Enter 3D printing – a game-changer that has been making waves across industries.

Our mission is to provide you, decision-makers, with valuable insights on how businesses can leverage 3D printing to achieve cost savings without compromising quality. We understand that your primary concern is not just the bottom line but also the performance, reliability, and durability of the parts you produce.

It’s about finding the sweet spot where cost-effectiveness meets production-grade excellence. Here are the top advantages of additive manufacturing when compared to traditional manufacturing, not that they need to be pitted against one another. Often, using them in tandem can unlock new efficiencies in your manufacturing workflows.

Key Differences Between Additive Manufacturing and Traditional Manufacturing

| Additive Manufacturing | Traditional Manufacturing | |

| Geometry | No limitations, Intricate internal structures and organic shapes | Limitations in achieving complex geometries |

| Customization | Can be tailored to specific requirements | Customization often comes with increased costs |

| Waste Reduction | Minimal waste material, Less cost and environmental impact | Byproducts and waste materials |

| Facility Requirements | Desktop machines need a workshop environment with little space compared to other options | Industrial systems require a large amount of space |

| Key Advantage | Mass Customization | Mass Production |

The top reasons why manufacturers are adding 3D printing technology to their workflows include:

- Ease of creating individually tailored parts for specific client requirements.

- Cost cutting by producing parts on an as-needed basis instead of relying solely on mass production.

- Ability to iterate fast with same-day prototypes

- Lightweighting by using new geometries produced with additive materials

Let’s dig into each of these in more depth.

3D Printing Advantage #1: Customization without Added Costs

In traditional manufacturing, customization often comes with increased costs due to the need for specialized molds or tool adjustments. Additive manufacturing excels in customization without additional expenses. Each part can be individually tailored, allowing businesses to meet specific client requirements or adapt products to changing market demands without ballooning production costs.

3D Printing Advantage #2: On-Demand Production: Reducing Inventory Costs

Additive manufacturing facilitates on-demand production, allowing businesses to produce items as needed, reducing the need for large inventories. This approach minimizes storage costs and the risks associated with overproduction. With additive manufacturing, businesses can respond swiftly to market demands, producing only what is necessary and optimizing inventory management. It’s important to note that while additive manufacturing is great for customization, it’s not impossible to also use it to mass produce customized parts and products.

3D Printing Advantage #3: Prototyping Savings: Fail Fast, Fail Cheap

Prototyping is a crucial phase in product development. Traditional prototyping methods can be time-consuming and expensive. Just how long does a prototype take to produce? Through traditional old-school manufacturing compared to 3D printing, we’re talking weeks or months versus a same-day turnaround.

Additive manufacturing offers a cost-effective solution for rapid prototyping. Businesses can iterate designs quickly and inexpensively, reducing the time and costs associated with traditional prototyping processes, which means you can get your product in market quicker.

3D Printing Advantage #4: Lightweighting Opportunities: Cost-Effective Materials

Additive manufacturing allows for intricate internal structures and the optimization of part geometries. This opens avenues for creating lightweight yet durable components, reducing material costs without compromising strength. Not only that but extreme precision is also on the table when it comes to 3D printing. Businesses can capitalize on this capability to design and produce cost-effective, high-performance parts.

In conclusion, additive manufacturing gives businesses many opportunities to achieve cost savings while maintaining and enhancing product quality. By reimagining manufacturing processes, minimizing waste, and embracing the flexibility of 3D printing, businesses can position themselves at the forefront of efficiency and innovation in the ever-evolving world of manufacturing.