SLS 3D Printing Services

Best of Both Worlds

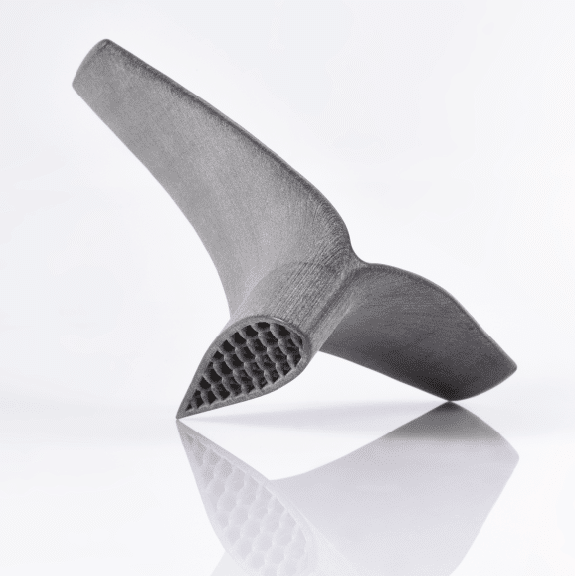

Selective Laser Sintering (SLS) parts boast both mechanical strength and aesthetics

Typically printed in Nylon, SLS is a powder-based process that has been around since the 80s and produces complex, organic geometries due to the lack of necessary support material.

This method works well for end-use functional parts, has a large build volume compared to other powder-based 3D printing technologies, is easy to be dyed in vibrant colors, and has isotropic mechanical properties.

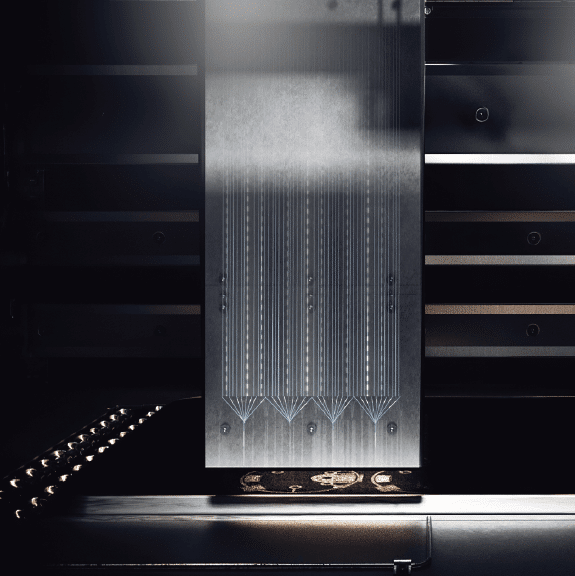

How SLS 3D Printing Works

SLS is a powder-based 3D printing system that starts by spreading a thin layer of powder over the build plate. Then, using layers, sinters the cross-sectional area of the part for that layer, fusing point to point.

This layer drops and a new layer is started. The build is cooled, extracted, and excess powder is removed with glass media bead blast. This creates the natural finish look for SLS parts.

Explore Popular Uses for SLS 3D Printing

- Functional end-use parts

- Complex geometries such as lattice or patterns

- Jigs, fixtures, etc.

- Consumer goods

- Snap fits, living hinges, and other mechanical joints

- Short run, end-use production components

Technical Specifications

|

|

SLS 3D Printing

|

|---|---|

|

Lead Times

|

Standard: 4 – 6 days | Expedited: as soon as next day

|

|

Standard Accuracy

|

+/-.012″ or +/-.003 in/in, whichever is greater.

|

|

Layer Thickness

|

40 microns.

|

|

Finish

|

Standard (natural white), dye black, vapor smoothed.

|

|

Available Materials

|

Nylon PA 12 (white), Nylon PA 12 GB, TPU 88A, PA 11

|

|

Minimum wall thickness

|

.030".

|

|

Minimum clearance for assemblies

|

0.020”.

|

|

Minimum feature size

|

0.030”

|

|

Minimum hole diameter

|

0.040”

|

Frequently Asked Questions

This process does not produce parts with different infills, instead it produces the part from exactly what the CAD file has with 100% infill.

FDM/FFF processes are the only processes that allow for different infill percentages unless it is designed in the part.

SLS advantages:

- Parts start off with a white color base for the part, which is ideal for different finishing options

- SLS printers offer a larger build volume for large, complex parts

SLS disadvantages:

- The inside of the part is porous, whereas Jet Fusion is solid with minor surface porosity

- The SLS 3D printing process takes slightly longer than HP Jet Fusion 3D printing.

Large, dense parts create longer print time, more material consumption, and often create surface defects in the part.

To resolve these issues, it is recommended you add a shell or hollow feature (2-3mm) to these parts.