Customers use A3D as their trusted partner for their toughest manufacturing problems across the entire product lifecycle. Additive and traditional manufacturing services, and Markforged material orders for Aerospace costumers. If you’re looking to scale-up efforts for a particular project by outsourcing jobs, A3D can help. We offer on-demand 3D printing for HP Jet Fusion, Stratasys, Markforged, Formlabs, post-processing, CNC machining, injection molding, and cast urethane services.

We’ll cover three important use-cases and how we can add value in the post below, including how we:

- Assisted a consumer goods brand in the medical device space by helping to cut their production lead time by 67% by introducing 3D printing for custom-fit products, enabling delivery in under two weeks.

- Advised Interlink Engineering, complementing their prototyping and product process development.

Use Case #1 A3D for Aerospace and Defense Suppliers: Onsite Builds that Save Time, Money, and Potentially Lives

| Industry | Aerospace and Defense Supplier/Manufacturer |

| Why A3D? | ISO certified, proven clients in defense/aerospace industry, intricate supplier network in additive manufacturing and other manufacturing technologies (know the right people.) |

| Why Now? | Heightened global tensions, importance of building up new technology infrastructure to support defense initiatives. |

| Use-Case | Hide in plain sight advanced technology to protect troops on the battlefield, eliminate supply chain issues. |

| What’s Next? | This company has already secured contracts with the Pentagon and Lockheed Martin with plans to create a self-sufficient drone factory that can be stationed inside a shipping container |

How Does a Defense Manufacturer Utilize A3D?

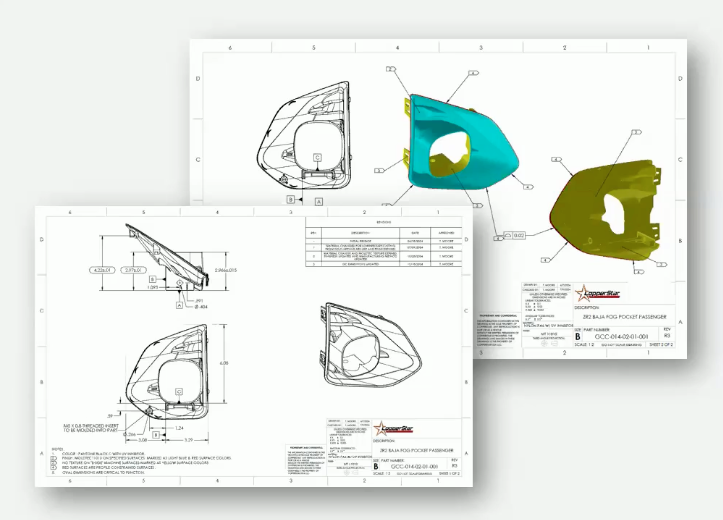

Finding the right manufacturing partner is challenging without a word-of-mouth recommendation. To complicate it further, getting part and product designs from concept to production is tough, and many manufacturing as a service firms won’t take on smaller contracts under $10,000. A3D takes on small projects all the way up to multimillion-dollar projects, and we’re AS9100 and ISO 9001:2015 certified.

That’s why many in the aerospace and defense industry choose to partner with us. For one UAS(Unmanned Aircraft System) company, A3D’s high standards for quality created a flow of steady parts in seven separate projects that supported the customer through its Beta phase of designing components specifically for the MJF (Multi Jet Fusion) process to optimize mechanical properties, dimensional accuracy, and aesthetics.

The first two projects completed by A3D produced and entire drone body, including the fuselage, wings, rutter, and tail, all printed in MJF PA12. The customer has a vision of leveraging A3D for its supply chain to scale up and down production to match demand.

Use Case #2 A3D for Medical Devices: Custom Orthotics and Facial Prosthesis

| Industry | Medical Device Supplier/Manufacturer |

| Why A3D? | ISO-certified, proven clients in the medical device industry, medical-grade 3D printers, and 3D printing materials expertise and availability. |

| Why Now? | Speed up production, decrease costs, and increase customization/benefit to the customer/patient. |

| Use-Case | Custom 3D-printed insoles to alleviate foot pain and arthritis issues from the convenience of your smartphone. |

| What’s Next? | Continue to expand an already successful business model and leverage AI to increase fit and customization, with the potential to expand to new product lines. |

How Does a Medical Device Manufacturer in the Consumer Goods Sector Utilize A3D?

A3D also partners with companies in the medical device space like FitMyFoot, which decreased their cart-to-door time by 67% by using A3D. Traditional manufacturing methods meant it used to take two months to produce custom orthopedic footwear. FitMyFoot wanted to disrupt the process by adding 3D printing technology to produce customized products for their customers in a fraction of the time. Customers get their custom 3D-printed insoles in two weeks or less.

How A3D helped FitMyFoot decrease time-to-market by two-thirds:

- Streamlined their creation of custom products with A3D’s fleet of 3D printers and additive manufacturing services.

- Automatic creation of a 3D print file from pictures of customer’s feet with a custom algorithm.

- Utilized HP Jet Fusion 4200 & 5200 series printers for three different products: insoles, slides, and flip-flops.

For more on A3D and the medical industry, check out our co-webinar with HP, “Unlocking Medical Device Innovations with 3D Printing.”

Use Case #3 A3D for Engineering Services and Suppliers

| Industry | Engineering Services Supplier/Manufacturer |

| Why A3D? | ISO 9001:2015 certified, proven clients across multiple industries, trusted long-time partnership and collaboration between the two companies, breadth of knowledge and expertise, customer service, unique referral-ship program |

| Why Now? | Grow business and expand to new clients and subindustries |

| Use-Case | Consultation for purchasing of 3D printers, materials, selection of best services, software, and hardware for specific client needs, access to A3D’s manufacturing network |

| What’s Next? | Continue to expand already successful business models, help bring additive to more companies across North America, and help revitalize American manufacturing. |

How Does an Engineering Services Manufacturer Utilize A3D?

Interlink Engineering uses A3D as their partner for selecting which 3D printers to bring in-house and which ones are better covered by an outside supplier.

For the last 20 years, Interlink Engineering has provided clients with a complete engineering solution on-demand. They offer design, analysis, prototyping, and product process development. Their mission is to provide quality engineering services at competitive prices while reducing the cost and time to get projects completed.

How A3D partners with Interlink to speed up the design to manufacturing process:

- Interlink works with clients to design and bring parts and products to prototype.

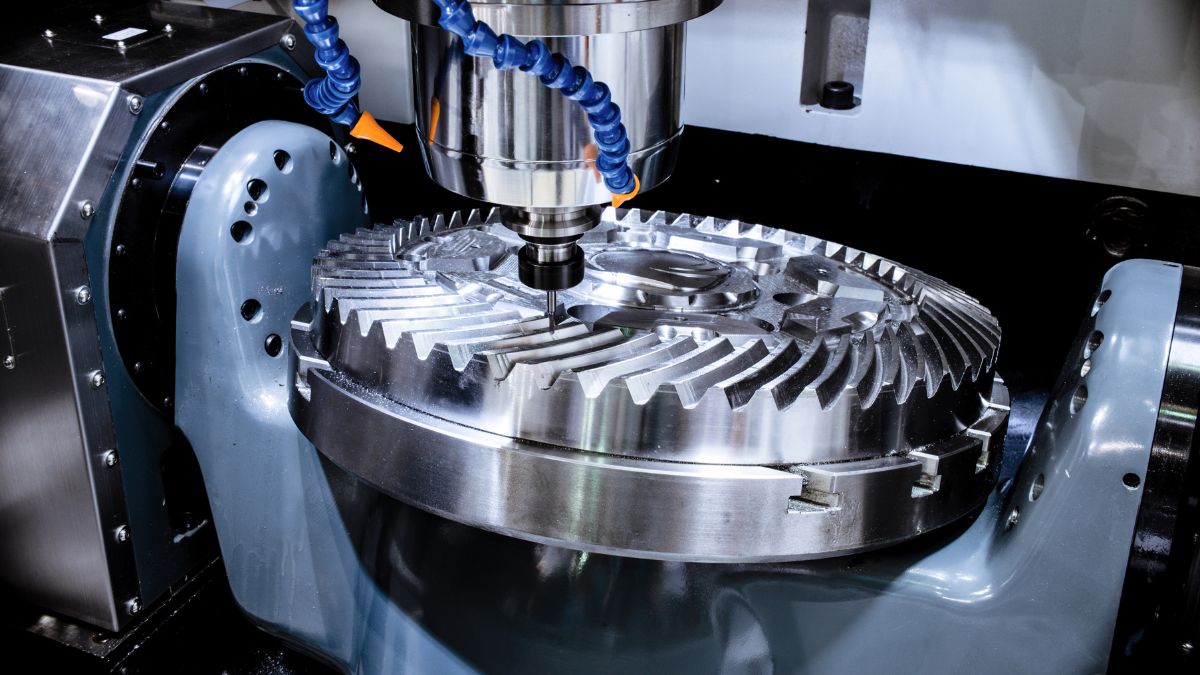

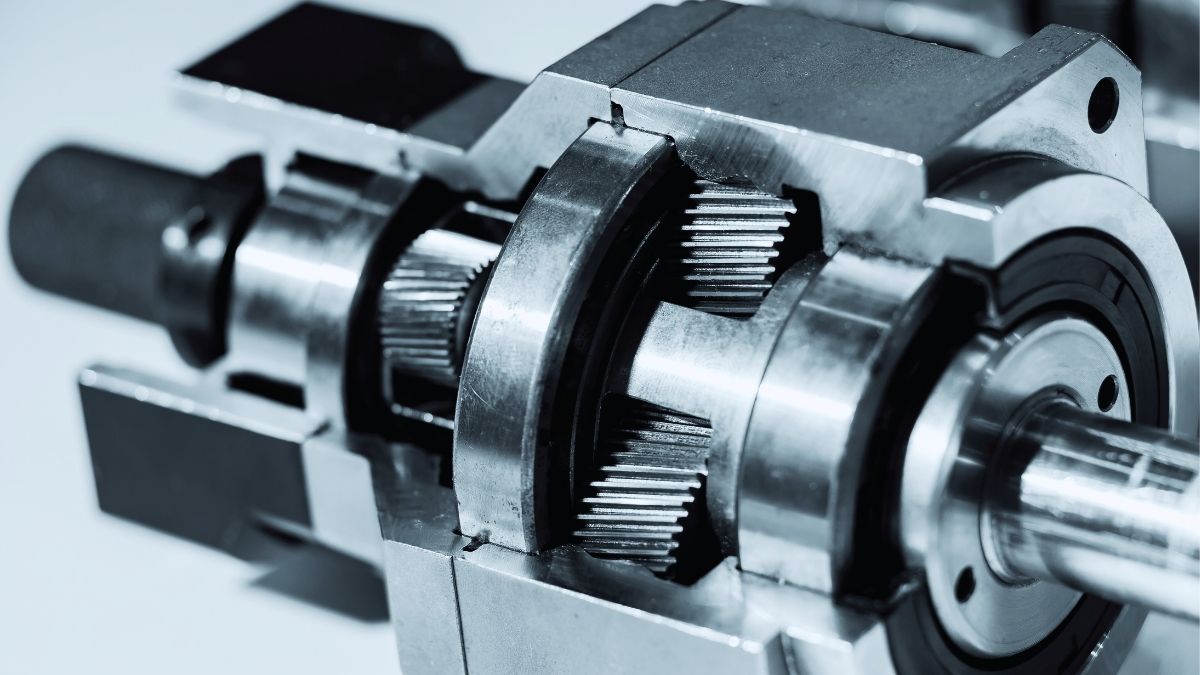

- When the customer needs precise manufacturing or things requiring machining precision or high-quality 3D printing, that’s where A3D comes in.

- Customers can utilize A3D’s fleet of additive manufacturing technologies and capabilities to create parts and products on time and within budget.

- A3D partnered with Interlink to help them select which 3D printer (They went with the HP MJF 5200) to start with for in-house jobs.

Dylann Pratt, Owner and Director of Engineering at Interlink Engineering, continues to work with A3D for their quick turnarounds and great customer service. When we asked him for advice on other companies and what’s working well with A3D, he had this to say:

“We do minimal manufacturing internally,” Pratt explained. “Anything that requires machining precision, higher accuracy or higher quality 3D printing, we are reaching out to A3D to do that.” Pratt says the partnership is helpful to reassure their clients. A3D can meet customers wherever they are when they reach the production phase.

“There are stair steps along the way to production,” Pratt illustrated. “A3D has options all along that staircase. Sometimes it’s 3D printing, cast parts, low-production molds, or getting machined. Even without a huge budget, you’ll be able to get to the point of releasing your product.”

About A3D

A3D is the leading industry-certified additive and traditional manufacturing as a service provider for professional-grade manufacturing. A3D offers on-demand training for HP Jet Fusion, Stratasys, Markforged, Formlabs, post-processing, CNC machining, injection molding, and cast urethane services.

Ready to scale your production process with A3D? Contact us today.