PA12, Polyamid 12, and Nylon12: Three Interchangeable Names for the Same Material

No matter what you call it, PA12, Nylon12, or it’s more formal name, Polyamid 12, is one of the most versatile and useful materials for 3D printing, and we’re going to show you why you’ll want to use it over other types of additive manufacturing materials with the MJF printing system.

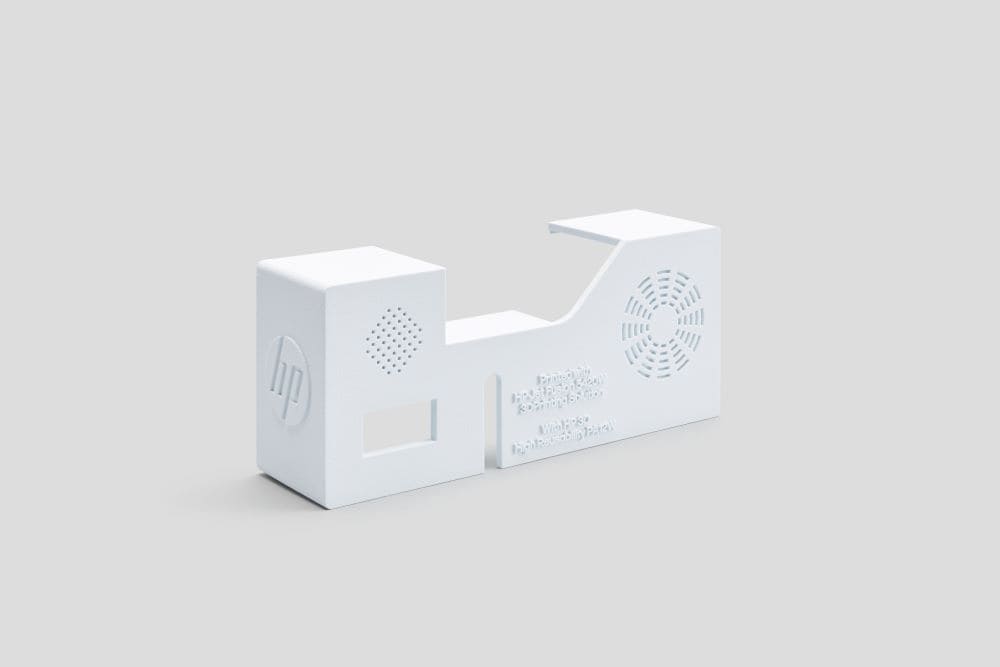

Using PA12 in MJF technology lets builders create intricate prototypes to durable end-use parts including complex assemblies, housings, enclosures, and more. It’s a robust and highly flexible thermoplastic polymer that’s ecofriendly (made from recycled materials), and because it’s white, it’s easy to dye bright colors during post-processing for customization.

When you use PA12 with HPs Multi Jet Fusion printing systems, it undergoes some neat changes in terms of its surface finish, mechanical properties, and final look. Then the material is formally called, “HP MJF PA12 White.”

HP Multi Jet Fusion (MJF) technology is widely known as the industry standard for fast, high-quality, and precise 3D prints whether you’re creating intricate mechanically engineered models or high-performance functional parts.

HP Multi Jet Fusion Material PA12: Properties and Characteristics

For a material made from recycled cooking oil, HP MJF PA12 White has some pretty great characteristics that make it ideal for 3D printing — it’s super strong, has a great finish, is water-tight, and its biocompatible.

It’s used widely in a diverse set of applications due to its key advantages in strength to weight ratio, chemical resistance, and it requires minimal post-processing.

Key Advantage 1: PA12 Has an Extremely High Strength-to-Weight Ratio

One of its most striking features is its exceptional strength-to-weight ratio. With the MJF, PA12 can be used to craft functional prototypes that undergo rigorous testing or produce end-use parts that demand durability without adding unnecessary bulk.

Its ability to maintain structural integrity across complex geometries positions it as a versatile solution for projects requiring intricate detailing and unconventional shapes.

Key Advantage 2: PA12 has a Smooth Surface Finish Ideal for Minimal Post Processing

The smooth surface finish of HP MJF PA12 White is another hallmark of its excellence. By minimizing post-processing efforts, it streamlines the manufacturing workflow, allowing for quicker turnaround times without compromising on quality. This trait not only enhances efficiency but also ensures that the final product meets the highest standards of aesthetics and functionality.

Key Advantage 3: Chemically Resistant Oils, Greases, Aliphatic Hydrocarbons

PA12’s innate resistance to chemicals broadens its utility across many industries.

In the automotive sector, where components are subjected to harsh environments and corrosive substances, HP MJF PA12 White maintains its integrity and performance over time. Similarly, in aerospace applications where reliability is paramount, its ability to withstand chemical exposure elevates it to a material of choice for critical components.

Even in the realm of consumer goods, where versatility and longevity are prized, PA12 proves its worth, offering a robust solution for a myriad of products ranging from household appliances to electronic gadgets.

HP MJF PA12 White Applications and Industries

The adaptability of HP MJF PA12 White extends far beyond its initial capabilities. It’s used in so many different industries and applications it would be insane to try to cover them all here. Just know, it’s highly versatile.

Industry Applications: Medical Device and Energy

PA12 can be used with MJF technology to create things like biocompatible and medical-grade prosthetics like cranial remolding orthosis devices to treat head shape deformities in infants (like plagiocephaly.) Learn more about additive manufacturing in the medical device space.

And, because it’s water-tight, it’s used in infrastructure projects such as on the insides of steel pipes for wastewater or oil and gas transport.

Industry Applications: Automotive

In automotive manufacturing, where the pursuit of lightweight yet durable components is important, HP MJF PA12 White is a good material choice due to the strength-to-weight ratio for:

- Robust brackets that support critical systems

- Lightweight housings that protect vital components

- Intricate interior parts that seamlessly blend aesthetics with functionality

PA12 lets automotive engineers achieve a balance between performance, efficiency, and design flexibility, enhancing vehicle performance and driving experience.

Industry Applications: Aerospace, Consumer Goods, and Electronics

PA12’s strength and heat resistance render it ideal for a range of applications for aerospace, including ducting that precisely channels airflow to brackets for securing critical systems in place.

HP MJF PA12 White is also used in customized consumer goods products tailored to individual preferences to prototyping custom packaging designs.

Additionally, its role in producing consumer electronics enclosures underscores its ability to merge form with function seamlessly, offering both aesthetic appeal and robust protection for delicate electronics. By harnessing the power of HP MJF PA12 White, manufacturers in the consumer goods industry can unleash their creativity, bringing to life products that inspire and delight consumers worldwide.

One of the Most Ecofriendly Materials You Can Use in Additive: PA12’s Sustainability and Environmental Impact

Beyond its technical prowess, HP MJF PA12 White stands out as a champion of sustainability, offering a multifaceted approach to eco-conscious manufacturing. At its core lies Nylon 12, a recyclable thermoplastic renowned for its durability and versatility. The recyclability of Nylon 12 allows for the efficient reuse of excess material, significantly reducing waste in the manufacturing process. By implementing closed-loop recycling systems, companies can further minimize their environmental footprint, ensuring that discarded material is repurposed rather than ending up in landfills or incinerators.

The efficiency of MJF technology plays a pivotal role in enhancing sustainability efforts. Unlike traditional manufacturing methods that often involve subtractive processes resulting in significant material wastage, MJF operates on an additive principle, depositing material only where needed. This precise material deposition not only conserves resources but also minimizes energy consumption, as the process only requires the energy necessary for melting and fusing the material.

Additionally, MJF technology enables on-demand manufacturing, reducing the need for large inventories and excess production runs, thereby lowering overall carbon emissions associated with transportation and storage.

HP MJF PA12: A Sustainable Choice That Will Help You Meet Carbon Goals

By choosing HP MJF PA12 White, companies can actively align with sustainability goals without compromising on performance or quality. The material’s recyclability, coupled with the efficiency of MJF technology, offers a compelling proposition for industries striving to minimize their environmental impact while maintaining competitiveness in the market. Whether it is reducing material waste, conserving energy, or lowering carbon emissions, HP MJF PA12 White represents a tangible step towards a more sustainable future in manufacturing.

Read more about the Multi Jet Fusion in our guide covering how it works, material selection, and more.

Have questions? Contact our team at A3D Manufacturing today.